Product Detail

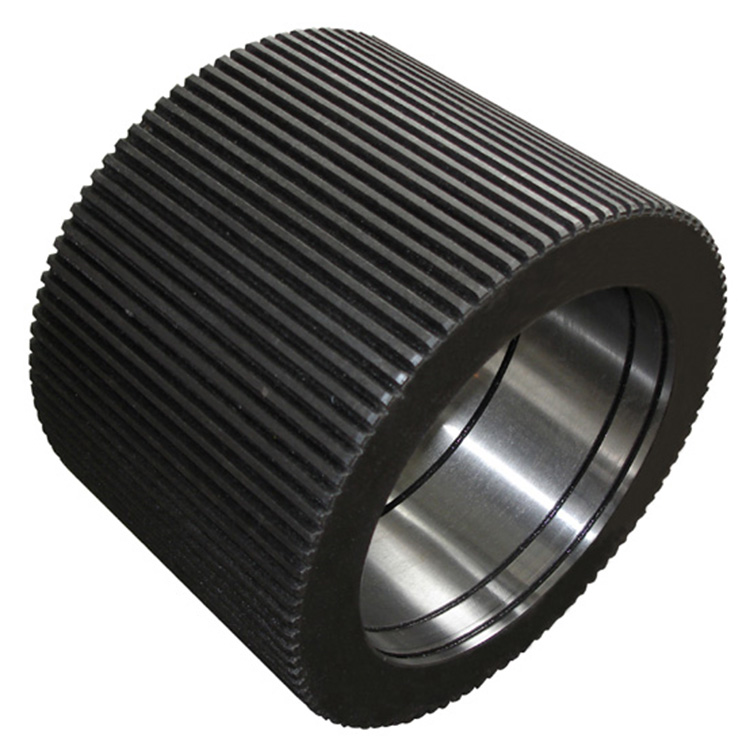

Roller shells

Product Introduction

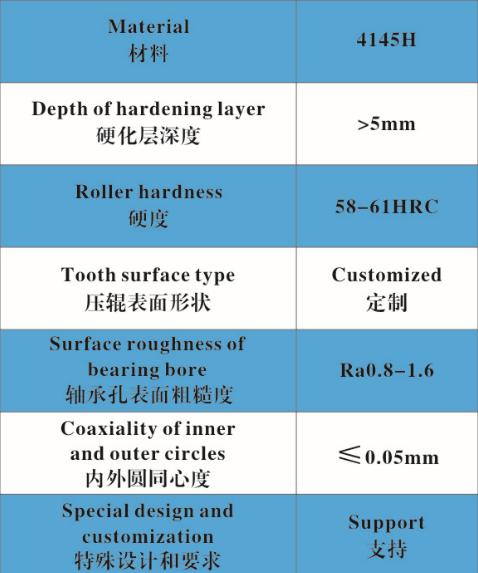

1. Choose high quality low carbon alloy carburized steel, medium carbon alloy steel, surface reinforcement treatment, deep wear resistance.

2. Choose bearing steel, the overall quenching, wear resistance on the surface, super high life and high cost performance.

3. Rich surface type selection: chute open line tooth, no open line tooth, honeycomb round hole type, hole straight tooth combination type, large spiral oblique tooth type, font tooth type, etc.

4. Provide detailed tooth type design and roller hardness customization to adapt to the special granulation environment.

5. High precision concentric grinding processing technology, inner hole and bearing with precision, internal and outer circle high coaxicity, stable quality.

Product Advantage

1.Hole+ Teeth

2.Full Dimples

3.Skewed Teeth

4.Straight Teeth

5.Customized by Client