Product Detail

Monotail

Product Introduction

Monotail adopts new design of short tail structure, which effectively improves the structural strength of rivet grooves and reduces the manufacturing cost. The rivet adopts full spiral groove structure, which has the larger grip range. The standard and thickened flanges are designed for the collar, which can meet the riveting requirements under different working conditions. The positioning for rivet installation has been improved to increase the success rate of installation. And working condition of riveting tool has been optimized to prolong its service life. Compared with other types of fastening connection, monotail has advantages of high connection strength, good reliability, superior vibration resistance, outstanding fatigue resistance, convenient installation, maintenance-free, etc.

Product Advantage

① High connection strength

② Superior vibration resistance

③ Good reliability

④ Prevent delayed fracture

⑤ Convenient installation

⑥ Maintenance-free

⑦ No noise

⑧ Reusable rivet

Product Parameters

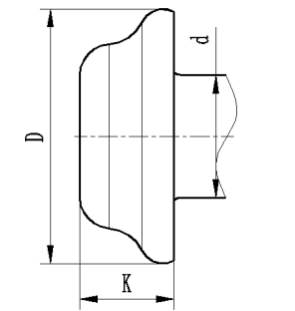

① Basic dimension of rivet

|

d |

Pan head |

Effective stress area As(mm2) |

|||||

|

D |

K |

||||||

|

Diameter/mm |

min |

max |

min |

max |

min |

max |

|

|

12 |

11.5 |

12.1 |

24.1 |

25.4 |

8.9 |

9.6 |

92.1 |

|

14 |

13.5 |

14.1 |

28.6 |

30.0 |

10.8 |

11.5 |

126.6 |

|

16 |

15.5 |

16.1 |

32.3 |

33.8 |

11.4 |

12.2 |

163.2 |

|

20 |

19.5 |

20.1 |

40.3 |

42.4 |

15.0 |

16.0 |

255.5 |

|

22 |

21.2 |

22.2 |

45.0 |

48.3 |

16.1 |

18.2 |

309.6 |

|

24 |

23.2 |

24.2 |

49.0 |

52.3 |

16.8 |

18.9 |

369.0 |

|

27 |

26.2 |

27.2 |

50.0 |

55.3 |

17.9 |

20.0 |

465.8 |

|

30 |

29.2 |

30.2 |

57.0 |

60.3 |

20.9 |

23.0 |

563.8 |

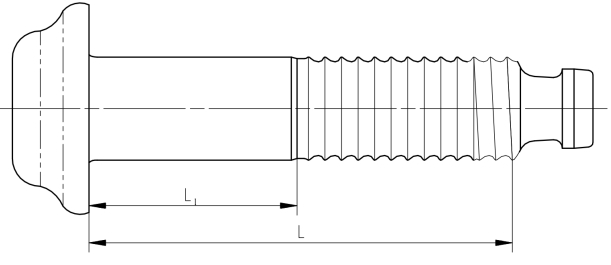

② Grip Range and Length

|

Grip range code |

Grip range |

Length of rivet |

|||||||||||||||

|

12 |

14 |

16 |

20 |

||||||||||||||

|

5 |

2 |

12 |

31.2 |

1 |

34.2 |

1 |

37 |

1 |

42.9 |

1 |

|||||||

|

10 |

5 |

15 |

34.2 |

4 |

37.2 |

4 |

40 |

4 |

45.9 |

4 |

|||||||

|

15 |

10 |

20 |

39.2 |

9 |

42.2 |

9 |

45 |

9 |

50.9 |

9 |

|||||||

|

20 |

15 |

25 |

44.2 |

14 |

47.2 |

14 |

50 |

14 |

55.9 |

14 |

|||||||

|

25 |

20 |

30 |

49.2 |

19 |

52.2 |

19 |

55 |

19 |

60.9 |

19 |

|||||||

|

30 |

25 |

35 |

54.2 |

24 |

57.2 |

24 |

60 |

24 |

65.9 |

24 |

|||||||

|

35 |

30 |

40 |

59.2 |

29 |

62.2 |

29 |

65 |

29 |

70.9 |

29 |

|||||||

|

40 |

35 |

45 |

64.2 |

34 |

67.1 |

34 |

70 |

34 |

75.9 |

34 |

|||||||

|

45 |

40 |

50 |

69.2 |

39 |

72.2 |

39 |

75 |

39 |

80.9 |

39 |

|||||||

|

50 |

45 |

55 |

74.2 |

44 |

77.2 |

44 |

80 |

44 |

85.9 |

44 |

|||||||

|

55 |

50 |

60 |

79.2 |

49 |

82.2 |

49 |

85 |

49 |

90.9 |

49 |

|||||||

|

60 |

55 |

65 |

84.2 |

54 |

87.2 |

54 |

90 |

54 |

95.9 |

54 |

|||||||

|

65 |

60 |

70 |

89.2 |

59 |

92.2 |

59 |

95 |

59 |

100.9 |

59 |

|||||||

|

70 |

65 |

75 |

94.2 |

64 |

97.2 |

64 |

100 |

64 |

105.9 |

64 |

|||||||

|

75 |

70 |

80 |

99.2 |

69 |

102.2 |

69 |

105 |

69 |

110.9 |

69 |

|||||||

|

80 |

75 |

85 |

104.2 |

74 |

107.2 |

74 |

110 |

74 |

115.9 |

74 |

|||||||

|

85 |

80 |

90 |

109.2 |

79 |

112.2 |

79 |

115 |

79 |

120.9 |

79 |

|||||||

|

90 |

85 |

95 |

114.2 |

84 |

117.2 |

84 |

120 |

84 |

125.9 |

84 |

|||||||

|

95 |

90 |

100 |

119.2 |

89 |

122.2 |

89 |

125 |

89 |

130.9 |

89 |

|||||||

|

100 |

95 |

105 |

124.2 |

94 |

127.2 |

94 |

130 |

94 |

135.9 |

94 |

|||||||

|

105 |

100 |

110 |

129.2 |

99 |

132.2 |

99 |

135 |

99 |

140.9 |

99 |

|||||||

|

110 |

105 |

115 |

134.2 |

104 |

137.2 |

104 |

140 |

104 |

145.9 |

104 |

|||||||

|

Grip range code |

Grip range |

Length of rivet |

|||||||||||||||

|

22 |

24 |

27 |

30 |

||||||||||||||

|

15 |

5 |

25 |

59.9 |

4 |

63.1 |

4 |

68.4 |

4 |

71.3 |

4 |

|||||||

|

20 |

10 |

30 |

64.9 |

9 |

68.1 |

9 |

73.4 |

9 |

76.3 |

9 |

|||||||

|

25 |

15 |

35 |

69.9 |

14 |

73.1 |

14 |

78.4 |

14 |

81.3 |

14 |

|||||||

|

30 |

20 |

40 |

74.9 |

19 |

78.1 |

19 |

83.4 |

19 |

86.3 |

19 |

|||||||

|

35 |

25 |

45 |

79.9 |

24 |

83.1 |

24 |

88.4 |

24 |

91.3 |

24 |

|||||||

|

40 |

30 |

50 |

84.9 |

29 |

88.1 |

29 |

93.4 |

29 |

96.3 |

29 |

|||||||

|

45 |

35 |

55 |

89.9 |

34 |

93.1 |

34 |

98.4 |

34 |

101.3 |

34 |

|||||||

|

50 |

40 |

60 |

94.9 |

39 |

98.1 |

39 |

103.4 |

39 |

106.3 |

39 |

|||||||

|

55 |

45 |

65 |

99.9 |

44 |

103.1 |

44 |

108.4 |

44 |

111.3 |

44 |

|||||||

|

60 |

50 |

70 |

104.9 |

49 |

108.1 |

49 |

113.4 |

49 |

116.3 |

49 |

|||||||

|

65 |

55 |

75 |

109.9 |

54 |

113.1 |

54 |

118.4 |

54 |

121.3 |

54 |

|||||||

|

70 |

60 |

80 |

114.9 |

59 |

118.1 |

59 |

123.4 |

59 |

126.3 |

59 |

|||||||

|

75 |

65 |

85 |

119.9 |

64 |

123.1 |

64 |

128.4 |

64 |

131.3 |

64 |

|||||||

|

80 |

70 |

90 |

124.9 |

69 |

128.1 |

69 |

133.4 |

69 |

136.3 |

69 |

|||||||

|

85 |

75 |

95 |

129.9 |

74 |

133.1 |

74 |

138.4 |

74 |

141.3 |

74 |

|||||||

|

90 |

80 |

100 |

134.9 |

79 |

138.1 |

79 |

143.4 |

79 |

146.3 |

79 |

|||||||

|

95 |

85 |

105 |

139.9 |

84 |

143.1 |

84 |

148.4 |

84 |

151.3 |

84 |

|||||||

|

100 |

90 |

110 |

144.9 |

89 |

148.1 |

89 |

153.4 |

89 |

156.3 |

89 |

|||||||

|

105 |

95 |

115 |

149.9 |

94 |

153.1 |

94 |

158.4 |

94 |

161.3 |

94 |

|||||||

|

110 |

100 |

120 |

154.9 |

99 |

158.1 |

99 |

163.4 |

99 |

166.3 |

99 |

|||||||

|

115 |

105 |

125 |

159.9 |

104 |

163.1 |

104 |

168.4 |

104 |

171.3 |

104 |

|||||||

|

120 |

110 |

130 |

164.9 |

109 |

168.1 |

109 |

173.4 |

109 |

176.3 |

109 |

|||||||

|

125 |

115 |

135 |

169.9 |

114 |

173.1 |

114 |

178.4 |

114 |

181.3 |

114 |

|||||||

|

130 |

120 |

140 |

174.9 |

119 |

178.1 |

119 |

183.4 |

119 |

186.3 |

119 |

|||||||

|

135 |

125 |

145 |

179.9 |

124 |

183.1 |

124 |

188.4 |

124 |

191.3 |

124 |

|||||||

|

140 |

130 |

150 |

184.9 |

129 |

188.1 |

129 |

193.4 |

129 |

196.3 |

129 |

|||||||

|

145 |

135 |

155 |

189.9 |

134 |

193.1 |

134 |

198.4 |

134 |

201.3 |

134 |

|||||||

|

150 |

140 |

160 |

194.9 |

139 |

198.1 |

139 |

203.4 |

139 |

206.3 |

139 |

|||||||

|

155 |

145 |

165 |

199.9 |

144 |

203.1 |

144 |

208.4 |

144 |

211.3 |

144 |

|||||||

|

160 |

150 |

170 |

204.9 |

149 |

208.1 |

149 |

213.4 |

149 |

216.3 |

149 |

|||||||

|

165 |

155 |

175 |

209.9 |

154 |

213.1 |

154 |

218.4 |

154 |

221.3 |

154 |

|||||||

|

170 |

160 |

180 |

214.9 |

159 |

218.1 |

159 |

223.4 |

159 |

226.3 |

159 |

|||||||

|

175 |

165 |

185 |

219.9 |

164 |

223.1 |

164 |

228.4 |

164 |

231.3 |

164 |

|||||||

|

180 |

170 |

190 |

224.9 |

169 |

228.1 |

169 |

233.4 |

169 |

236.3 |

169 |

|||||||

|

185 |

175 |

195 |

229.9 |

174 |

233.1 |

174 |

238.4 |

174 |

241.3 |

174 |

|||||||

|

190 |

180 |

200 |

234.9 |

179 |

238.1 |

179 |

243.4 |

179 |

246.3 |

179 |

|||||||

|

195 |

185 |

205 |

239.9 |

184 |

243.1 |

184 |

248.4 |

184 |

251.3 |

184 |

|||||||

|

200 |

190 |

210 |

244.9 |

189 |

248.1 |

189 |

253.4 |

189 |

256.3 |

189 |

|||||||

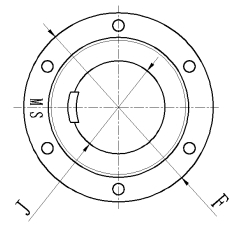

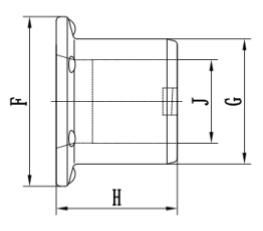

③ Basic dimension of collar

|

Nominal diameter/mm |

J |

G |

H |

F |

||||

|

min |

max |

min |

max |

min |

max |

min |

max |

|

|

12 |

12.1 |

12.3 |

18.3 |

18.5 |

17.3 |

17.7 |

24.1 |

25.4 |

|

14 |

14.1 |

14.4 |

21.2 |

21.4 |

20.2 |

21.0 |

28.2 |

29.6 |

|

16 |

16.1 |

16.4 |

24.2 |

24.5 |

23.1 |

23.7 |

32.2 |

33.8 |

|

20 |

20.1 |

20.5 |

30.2 |

30.8 |

28.9 |

29.7 |

40.2 |

42.1 |

|

22 |

22.1 |

22.6 |

33.2 |

33.9 |

31.8 |

32.8 |

44.3 |

46.5 |

|

24 |

24.1 |

25.1 |

36.3 |

37.3 |

34.6 |

35.6 |

48.9 |

50.5 |

|

27 |

26.8 |

28.0 |

40.5 |

41.9 |

39.3 |

40.9 |

55.1 |

56.3 |

|

30 |

29.7 |

31.4 |

45.1 |

47.1 |

43.1 |

45.0 |

61.2 |

62.8 |

④ Mechanical properties

|

Nominal diameter/mm |

Shear force/kN |

Clamp force/kN |

Tensile force/kN |

|

|

Acting on pin body |

Acting on locking groove |

|||

|

12 |

≥65.4 |

≥48.4 |

≥64.9 |

≥87.7 |

|

14 |

≥93.9 |

≥66.1 |

≥86.8 |

≥120.2 |

|

16 |

≥115.7 |

≥86.4 |

≥115.7 |

≥163.0 |

|

20 |

≥182.5 |

≥135.4 |

≥179.3 |

≥254.9 |

|

22 |

≥220.8 |

≥167.2 |

≥218.0 |

≥315.0 |

|

24 |

≥262.8 |

≥190.7 |

≥242.0 |

≥367.0 |

|

27 |

≥332.6 |

≥242.2 |

≥315.0 |

≥477.0 |

|

30 |

≥410.6 |

≥297.0 |

≥387.0 |

≥583.0 |