Product Detail

Hammers/Beaters

Product Introduction

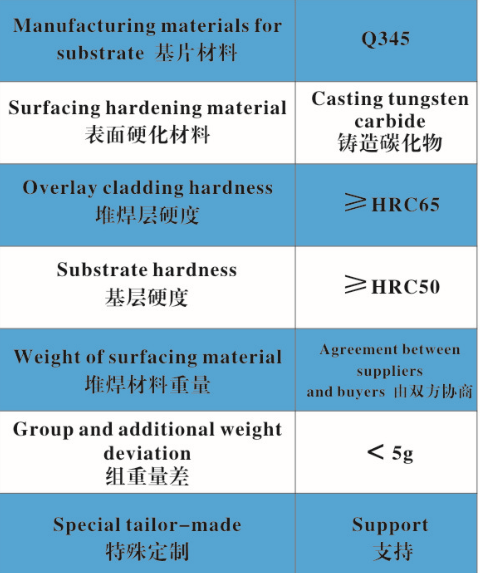

1. Manganese alloy steel is selected as the hammer substrate, which can obtain high hardness of 55 ~ 60 HRC through special process. Can effectively prevent the material abrasion.

2. Arms surfacing wear-resistant tungsten carbide, angular hardness can reach HRC 62-70. High efficiency strike material and has a high life.

3. Customizing the stacking welding form and thickness design of tungsten carbide according to different material crushing conditions, higher efficiency and capacity can be obtained.

4. The equipment is accurately weighed, the weight difference is less than 5 grams, and the small vibration of the equipment can effectively protect the host equipment.

Product Advantage

1. High striking resistance

2. High heat resistance

3. High fatigue resistance

Write your message here and send it to us